-

29 W. Pawnee, Bloomfield, NJ 07003

Difference and value of wood-fired vs electric-fired Jianzhan teacups.

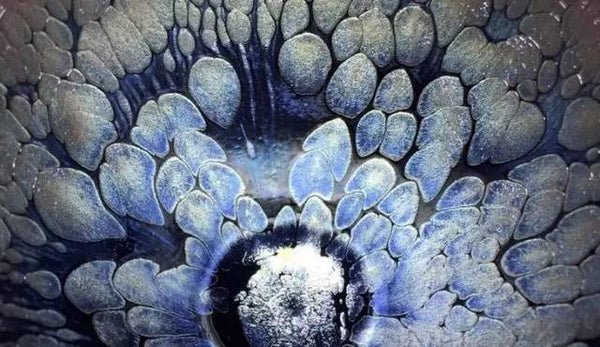

A Jianzhan teacup starts with a single glaze color, yet emerges from the kiln in a thousand varied hues. This is the greatest allure of wood-fired Jianzhan, as well as a testament to its extraordinary firing difficulty. Even within the same kiln—sometimes even when placed in the same box or container—Jianzhan pieces can exhibit drastically different glaze colors.

If a wood-fired Jianzhan and an electric-fired Jianzhan boast identical pattern effects, the wood-fired one will always be the preferred choice. Both types use exactly the same raw materials, but they differ in heating methods and kiln environments. Notably, wood-fired Jianzhan tends to have a smoother glaze, thanks to the warmer, more dynamic temperature conditions inside a wood-fired kiln.

Jianzhan crafting follows a unique set of principles, and the formation of its signature patterns (like hare’s fur or oil spots) demands extreme precision in timing and temperature. Step outside this narrow range, and the patterns will never form—this technical challenge applies to both electric-fired and wood-fired Jianzhan. However, electric firing allows for far better control over the firing process, enabling effects that are nearly impossible to achieve with wood firing. In terms of pattern consistency and variety, electric-fired Jianzhan has made remarkable progress: it has solved many technical bottlenecks that long plagued wood firing, laying the foundation for the modern Jianzhan industry’s growth. In turn, this industry development could theoretically boost advancements in wood-firing techniques—though so far, breakthroughs in wood-fired Jianzhan remain few and far between.

In ancient times, all Jianzhan were made using wood-firing techniques. With the invention of electricity in modern times, electric-fired Jianzhan emerged, followed by other modern methods (gas, coal, etc.). So, what sets traditional wood firing apart from these modern techniques?

Key Differences Between Wood-Firing and Modern Firing Techniques

To summarize, there are three core distinctions:

1. Bubble Texture: Dynamic vs. Uniform

Wood firing requires continuous addition of wood throughout the process, which causes constant temperature fluctuations. These fluctuations result in uneven bubble sizes in the glaze, creating a subtle sense of depth and layering. By contrast, modern gas and electric firing maintain stable temperatures, producing glazes with uniform, dense bubbles—a smooth, consistent texture, but lacking the organic variation of wood-fired pieces.

2. Glaze Color: Unpredictable vs. Stable

Temperature control in wood-fired kilns is extremely difficult; variations are inevitable. This unpredictability makes it nearly impossible to control Jianzhan’s final glaze color, often resulting in beautiful gradations of light and dark (e.g., a single piece might shift from deep black to soft gray). Modern gas kilns, however, can maintain a constant temperature, leading to highly stable glaze colors—every piece in a batch will have nearly identical hues.

3. Ash and Flame Marks: Natural Patina vs. Controlled Finish

In wood-fired kilns, wood ash and flames easily enter the chamber and settle naturally on the Jianzhan’s surface. During prolonged high-temperature firing, this ash fuses with the glaze, creating a warm, multi-layered patina—often with subtle specks, streaks, or “flame kisses” (light scorch marks) that tell the story of the firing process. Modern techniques, by design, avoid such natural interference, resulting in cleaner, more uniform glazes.

It’s important to note: these are just general guidelines for distinguishing firing methods. Advanced modern techniques can now replicate some wood-fired effects (e.g., simulated ash specks). Thus, the above differences should be used as references, not absolute rules.

Why Are Wood-Fired Jianzhan Teacups So Expensive?

The high cost of wood-fired Jianzhan stems from the countless constraints of wood-kiln firing:

1. Strict Regulatory Restrictions

To protect forest resources, governments strictly prohibit wood firing in most cases—only a handful of operations receive special approval. This scarcity of legal wood-firing facilities immediately limits supply, driving up costs.

2. High Financial and Technical Barriers

Wood firing demands significant investment: building a traditional wood kiln is costly, and sourcing large quantities of high-quality firewood (suitable for consistent burning) adds ongoing expenses. Technically, it’s far from “building a simple stove and firing with a few pieces of wood”—mastering wood firing requires years of experience to judge temperature, adjust wood addition, and anticipate kiln behavior. Few artisans possess this expertise.

3. Ancient Craft, Modern Aesthetics

Wood firing is an ancient technique: in ancient times, potters would cover Jianzhan bodies to isolate them from wood ash, preventing ash deposits or flame marks (seen then as flaws). Today, however, modern aesthetics have shifted—contemporary wood-firing pursues the natural fusion of wood ash and clay, turning those once-unwanted marks into prized features. This shift requires reimagining traditional methods, adding another layer of craft complexity.

4. Unpredictability and Uniqueness

Kiln masters can never fully predict the outcome of a wood-firing batch. Fires fluctuate, ash settles randomly, and temperatures shift—yet one thing is certain: every wood-fired Jianzhan is one of a kind. No two pieces will have the same ash patterns, flame marks, or glaze gradations. This uniqueness, born from unpredictability, adds immense value.

Wood firing is a direct dialogue between the kiln master and the kiln itself—a primitive, unscripted process that creates extraordinary works of art. Wood-fired Jianzhan bear the marks of this dialogue: subtle contrasts between fired and less-fired areas, traces of dancing flames, and a quiet beauty that feels both ancient and profound. It is this irreplaceable charm that drives wood-firing artisans to dedicate years of their lives to mastering the craft—and why collectors are willing to pay a premium for these unique pieces.